|

Nutritional supplement

|

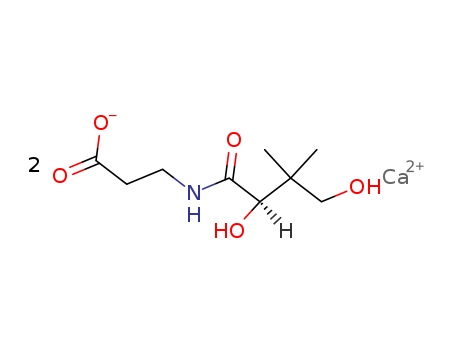

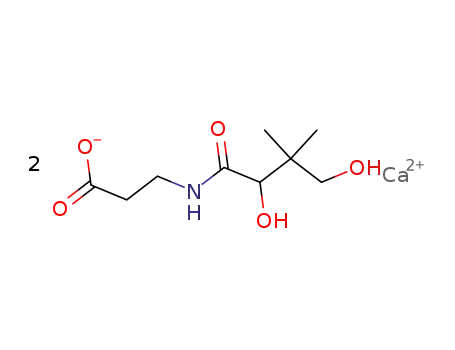

D-Calcium pantothenate as components of coenzyme A regulates the metabolism of protein, saccharide, and fat, and prevents diseases, which is indispensable substance for growth and development of domesticated creatures and fishes, for fatty synthesis and decomposition. The lack of D-calcium pantothenate would result in the slow growth of poultry and the malfunction of reproduction mechanisms. Therefore, D-calcium pantothenate as a growth factor is used in feed additives. In addition, D-calcium pantothenate is also as food enrichment widely used in food industries, sun as breakfast cereals, beverages, dietetic, and baby foods. D-Calcium pantothenate has the function of making antibodies and it plays an important role in the fight against pressure to maintain hair, skin and blood health, and also contributes to improving the deficiency and neuritis. Thus, it has broad medical value and has been applied in pharmaceutical industries that single-dose is used for pantothenic acid deficiency, complex of vitamins B and multivitamins are used for vitamin supplement, and other compounds with different components are widely used for gastrointestinal diseases, respiratory diseases, skin diseases, mental inactivity, neurasthenia, and so on.

|

|

Production method

|

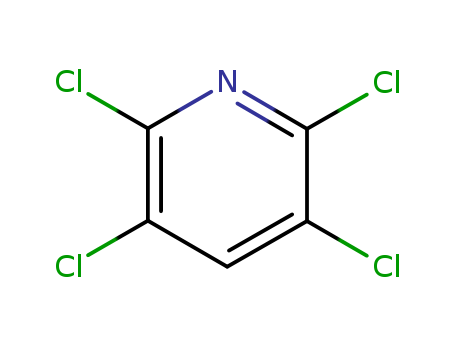

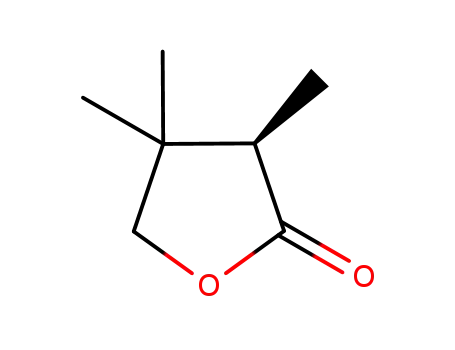

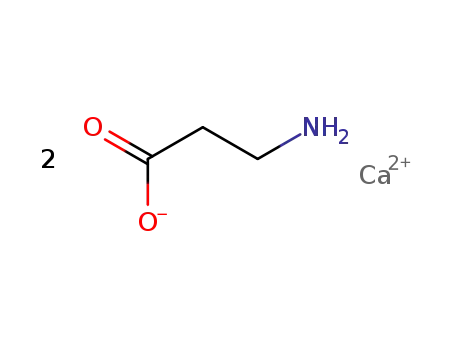

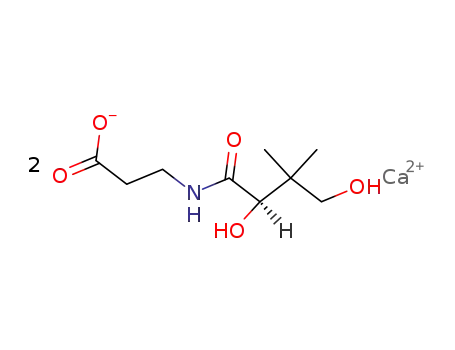

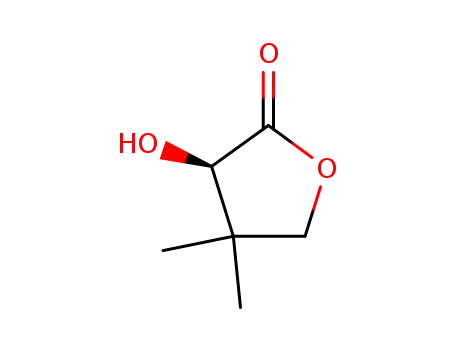

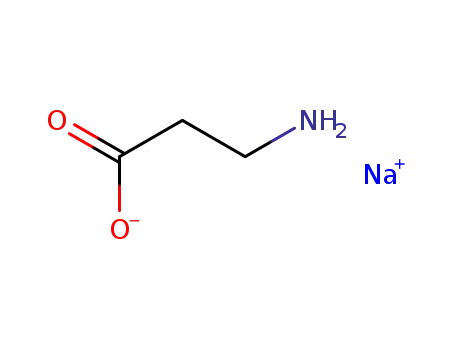

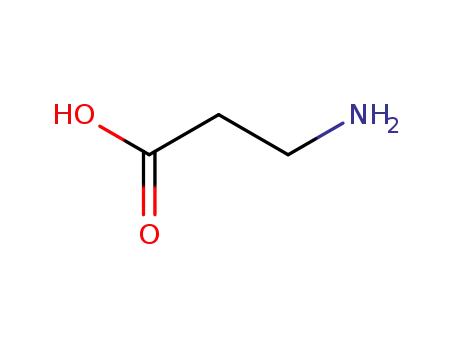

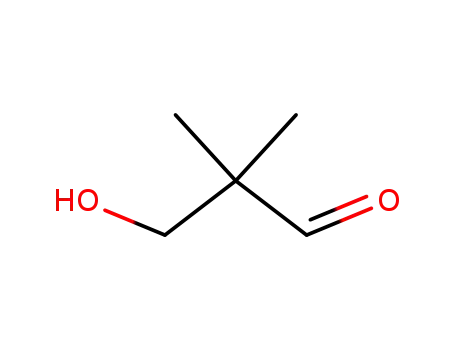

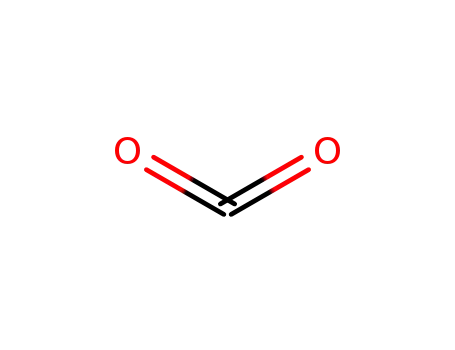

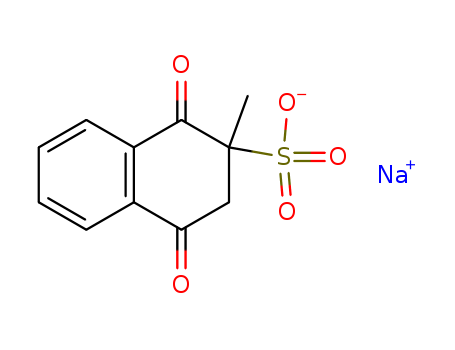

Take isobutyraldehyde as raw material; carry out hydroxymethylation, addition reaction, hydrolysis, acidification, lactonization and acylation to derive the final product. Formaldehyde and anhydrous potassium carbonate are sent into the reaction pot. At 14-20 °C, it is added dropwise of isobutyraldehyde. After the completion of the addition, incubate for stirring reaction for 3h, and then stand at 14-18 °C for 0.5 h to obtain the upper oil-2, 2-dimethyl-3-hydroxypropionaldehyde. 2, 2-dimethyl-3-hydroxypropanal is dissolved in 4 times the water while the sodium cyanide is dissolved in 6 times the water and calcium chloride dissolved in 2 times the water. The above solutions are successively added into the reaction pot. 50% sulfuric acid solution was added under stirring at 60-65 ° C for 6h; then being heated to 80-85 °C for 3h and subject to vacuum concentration to being thick. 95% ethanol was added to precipitate the inorganic salt and filtrate. After the recovery of ethanol through distillation under reduced pressure, collect the fractions of 130-145C (1.33-2.39 Kpa), namely ?-butyrolactone. Then, β-aminopropionic acid, 5/6 methanol and lime were successively added to the reactor. Raise the temperature to 40 °C, and the reaction was stirred for 2 hours. The reaction mixture was allowed to stand for while before the supernatant was filtered by filtration. The solid residue in the pot was washed with 1/6 methanol and then filtered. The filtrate is placed in another reaction pot, being added of γ-butyrolactone for stirring and dissolving in room temperature for 40 h reaction to generate calcium pantothenate. Stirring with water and cooling to-5-0 °C, and add seed crystal for stirring of 24 hours, filter to obtain the dextro calcium pantothenate. 2/3 the amount of calcium pantothenate and calcium p-pantothenate are thrown into the reaction pot; add methanol and water, heat to 40 °C for stirring dissolving and filter upon being hot. The filtrate is cooled to 15 °C, added of a small amount of calcium L-pantothenate and crystal for 2h. When the specific rotation is up to +6 °-+8 °, separate the crystal, and wash with a small amount of methanol to obtain the L-calcium p-pantothenate (still used for resolution). The remaining 1/3 racemic calcium pantothenate was dissolved in a filtrate of 35-40 ° C, filtered and cooled to 15 ° C. A small amount of calcium p-pantothenate was added and the crystals were incubated for 2 hours. Crystals were separated when the specific rotation was-0.8 °--0.6 °, washed with a small amount of methanol and dried in vacuo to give calcium dextrate. It is derived through the heating and condensation between calcium β-alanine and α-hydroxy β, β-dimethyl-γ-butyl ester.

|

|

Toxicity

|

LD50>10 g/kg (rat, oral); GRAS (FDA, § 182.5212, §184.1212, 2000);

|

|

Usage limit

|

GMP as the limit (FDA &184.1212, 2000); 1% in general food (calculated based on calcium excluding special nutritional supplements; Japan, 1993);

|

|

Hazards & Safety Information

|

Category: Toxic substances Toxicity classification: Low toxicity Acute toxicity: Oral-rat LD50: 10000 mg/kg; oral-mouse LD50: 10000 mg/kg Flammability and Hazardous characteristics: Thermal decomposition releases toxic nitrogen oxides Storage and transport characteristics Treasury: low temperature, ventilated and dry Fire extinguishing agent:? water, carbon dioxide, dry powder, foam

|

|

History

|

Pantothenic acid (PA), also known as vitamin B5, is essential to all forms of life. Its name is derived from the Greek word pantos that means “everywhere”, which is appropriate for this widely, distributed vitamin.

|

|

Reactions

|

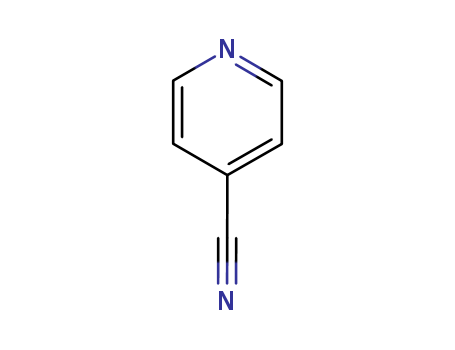

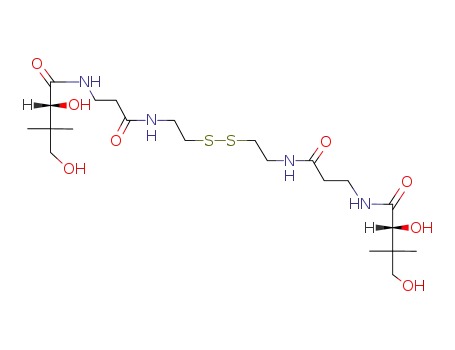

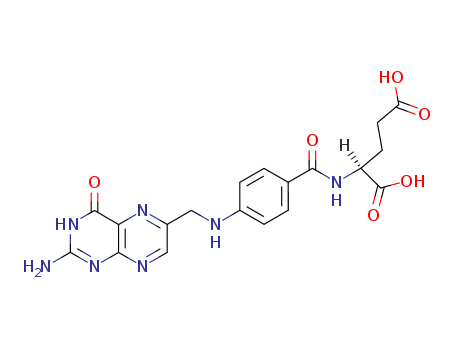

Pantothenic acid is a constituent of coenzyme A, which participates in numerous enzyme reactions. CoA was discovered as an essential cofactor for the acetylation of sulfanilamide in the liver and of choline in the brain.

|

|

Manufacturing Process

|

A mixture of 288 g (4 mols) of isobutyraldehyde, 288 g of methanol was cooled to 10°C and 170 g (2 mols) of 36.6% formalin containing 8.5 g (3% based on isobutyraldehyde) of sodium hydroxide was added dropwise over a 55 minute period to produce alpha,alpha-dimethyl-beta-hydroxy-propionaldehyde. The mixture was stirred for an additional 2 hours at 10-15°C and then contacted with acetic acid to neutralize the catalyst. The excess isobutyraldehyde and methanol were stripped off at a kettle temperature of 50°C at 25 mm. To the residual α,α-dimethyl-beta-hydroxypropionaldehyde a mixture of 260 ml of methanol and 2 g (0.75%) sodium cyanide was added and the solution cooled to 10°C before adding 59.4 g (2.2 mols) of hydrogen cyanide dropwise over a 35 minute period to produce α,γ-dihydroxy-β,β- dimethylbutyronitrile. The mixture was stirred at 10°C for one hour period and then contacted with acetic acid to neutralize the catalyst before stripping off the excess methanol to a kettle temperature of 45°C at 18 mm. The crude cyanohydrin was then hydrolysed by heating with 4 mols of concentrated hydrochloric acid at 80°C for 2 hours, then diluting with an equal volume of water and heating at 100°C for an additional 8 hours. The aqueous mixture was extracted continuously with ethylene dichloride. The solvent was removed, and pantolactone (B. P. 131°C/19 mm, M.P. 61-77°C, 96.5% purity by saponification) was obtained by distillation in 71.5% yield based on formaldehyde and 55% efficiency based on isobutyraldehyde.26 grams of racemic pantolactone (0.2 mol) and 1.1 grams of sodium methoxide (0.02 mol) contained in 30 ml of methanol, were added to 78.8 grams of 1-brucine (0.2 mol) contained in 156 ml of methanol. The resulting mixture was refluxed for 1.5 hours and allowed to stand at room temperature overnight. After centrifuging, washing with methanol and drying, 65.4 grams of D-(-)-pantolactone 1-brucine (62% of theory based upon all of the racemic pantolactone) melting at 203° to 206°C were obtained. Upon chilling the mother liquor, 13.46 grams of additional complex melting at 175° to 177°C were obtained.D-(-)-Pantolactone was obtained from the complex in the following manner. The 65.4 grams of complex obtained above were treated with 65 ml of chloroform and 5.35 grams of sodium hydroxide contained in 35 ml of water for one hour at room temperature. The aqueous layer was extracted 6 times with 20 ml portions of chloroform in order to remove the brucine. The sodium pantoate contained in the aqueous layer was relactonized by treatment with 11 ml of concentrated hydrochloric acid. Extraction of the crude D-(-)- pantolactone yielded 15.29 grams. This material was then recrystallized from 7 ml of methyl isobutyl ketone and 7 ml hexane thereby yielding 9.77 grams of D-(-)-pantolactone (37% of theory). The αD25 was -44.8°.Into a vessel equipped with an agitator and reflux condenser are placed approximately 52 parts by weight of α-hydroxy-β,β-di-methyl-γ-butyrolactone, approximately 36 parts by weight of β-alanine, about 40 parts by weight of diethylamine and about 100 parts by weight of anhydrous methanol. The mixture is stirred and refluxed for about 12 hours until the reaction is complete as evidenced by the dissolution of the β-alanine. To this resulting mass is gradually added 8 parts by weight of calcium metal nodules or pellets and refluxing continued until the metal is dissolved. The diethylamine and alcohol are distilled off until the residue becomes viscous. The viscous residue is dried under vacuum at 100°C. The solid residue recovered, as biologically assayed, indicated a 91% yield of calcium pantothenate.

|

|

Therapeutic Function

|

Vitamin

|

|

Biochem/physiol Actions

|

The calcium salts of panthenol are commonly used for pharmaceutical preparations. Pantothenate is a component of coenzyme A and is useful in its synthesis. Pantothenic acid is also involved in the synthesis of heme, cholesterol and fatty acids. Since vitamin B5 is found in all foods, its deficiency is not commonly observed.

|

|

Safety Profile

|

Moderately toxic by intraperitoneal, subcutaneous, and intravenous routes. Mildly toxic by ingestion. A vitamin. See also CALCIUM COMPOUNDS. When heated to decomposition it emits toxic fumes of NOx.

|

|

Purification Methods

|

The salt crystallises as needles from MeOH, EtOH or isoPrOH (with 0.5mol of isoPrOH). It is moderately hygroscopic. The S-benzylisothiuronium salt has m 151-152o (149o when crystallised from Me2CO). [Kagan et al. J Am Chem Soc 79 3545 1957, Wilson et al. J Am Chem Soc 76 5177 1954, Stiller & Wiley J Am Chem Soc 63 1239 1941, Beilstein 4 IV 2569.]

|

|

Member of Vitamin B Category

|

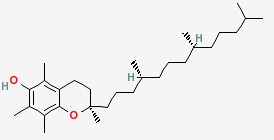

Calcium Pantothenate, also known as Vitamin B5 calcium salt or pantothenic acid, belongs to the vitamin B category. It is naturally found in animals and plants and is essential for various metabolic functions.

|

|

Role in Health Maintenance

|

Calcium Pantothenate plays a crucial role in maintaining blood health, promoting the creation of antibodies, and supporting healthy hair and skin. It contributes to enhancing neuritis and deficiency and is widely used in nutrient supplements, animal feed, pharmaceutical sciences, and other fields.

|

|

Component of Coenzyme A

|

Pantothenate, the active form of Vitamin B5, is a component of coenzyme A (CoA) and a part of the vitamin B2 complex.

Coenzyme A is essential for various metabolic processes, including the metabolism of carbohydrates, proteins, and fatty acids.

|

|

Emulsifier and Surfactant

|

While primarily known as a water-soluble vitamin, calcium pantothenate can also act as an emulsifier and surfactant. It contains amide nitrogen and a neopentyl glycol component, contributing to its emulsifying properties and oil solubility.

|

|

Use in Dermatological Therapies

|

Dexpanthenol, the stable alcoholic analog of calcium pantothenate, is widely used in dermatological therapies. It is utilized for its beneficial effects on skin health and wound healing.

|

|

Safety in Animal Nutrition

|

Calcium Pantothenate and D-panthenol are considered safe for use in animal nutrition, including feed and drinking water. They do not pose significant concerns for consumers, with low toxicity and minimal irritation potential.

|

|

Nutritional Role and Bioequivalence

|

Calcium Pantothenate serves as an effective source of pantothenic acid in domestic animals, supporting their nutritional needs.

D-Panthenol is regarded as a pro-vitamin that is essentially bioequivalent to pantothenic acid, providing similar benefits in animal nutrition and dermatological applications.

|

|

Chemical properties

|

It appears as white crystalline (methanol), being hygroscopic; it is stable to the light and air with its aqueous solution being weakly alkaline. Its Mp is 195-196 °C (decomposition); Specific rotation [α] 26D + 28.2 ° (5%, water); It is soluble in water and glycerol, being slightly soluble in acetone and ethanol;

|

|

Brand name

|

Calpan (BASF); Pantholin (Lilly).

|

|

General Description

|

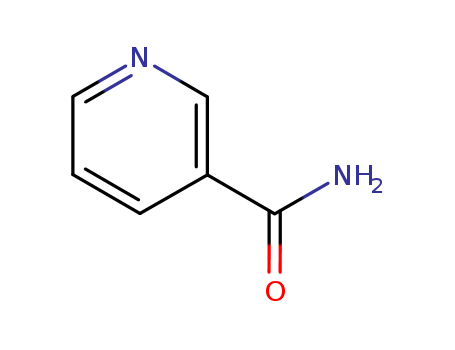

The first suggestion for the existance of vitamin B5 came from Carter et al. in 1930; although it was never characterized or isolated. This vitamin is synthesized by most green plants and microorganisms. Excellent sources of the vitamin are liver, egg yolk, whole grains, and fortified ready-to-eat cereals. However, as the original name implies, many foods contain sufficient pantothenic acid to supply dietary needs. Chemically, pantothenic acid is considered to be aβ-alanine derivative of the asymmetric pantoic acid and thus shows asymmetry. Only the naturally occurring D(+)- stereoisomer (with R configuration) is biologically active and the L(-)-stereoisomer (with S configuration) is inactive. When its carboxylate functional group is attached through an amide linkage with β-mercaptoethylamine, it is known as pantetheine (also spelled pantotheine). The biologically active form of pantothenic acid, CoA, is formed when the terminal alcoholic function of pantetheine is attached to ADP 3'-phosphate.

|

English

English 中文

中文

English

Japanese

Russian

Korean

गोंगेन हें नांव

Deutsch

Corsu

Guarani

Hausa

Cymraeg

Nederlands

Aymara

Français

Kreyòl ayisyen

čeština

ʻŌlelo Hawaiʻi

डोग्रिड ने दी

ภาษาไทย

հայերեն

فارسی

Hmoob

ދިވެހި

भोजपुरी

繁體中文

Türkçe

हिंदी

беларускі

български

tur

Gaeilge

ગુજરાતી

Magyar

Eesti keel

بالعربية

বাংলা

Azərbaycan

Português

Suid-Afrikaanse Dutch taal

کوردی-سۆرانی

Ελληνικά

español

Frysk

dansk

አማርኛ

Bamanankan

euskara

Italiano

Tiếng Việt

অসমীয়া

català

Suomalainen

Eʋegbe

Hrvatski

Cebuano

Gàidhlig na h-Alba

bosanski

galego

English

Japanese

Russian

Korean

गोंगेन हें नांव

Deutsch

Corsu

Guarani

Hausa

Cymraeg

Nederlands

Aymara

Français

Kreyòl ayisyen

čeština

ʻŌlelo Hawaiʻi

डोग्रिड ने दी

ภาษาไทย

հայերեն

فارسی

Hmoob

ދިވެހި

भोजपुरी

繁體中文

Türkçe

हिंदी

беларускі

български

tur

Gaeilge

ગુજરાતી

Magyar

Eesti keel

بالعربية

বাংলা

Azərbaycan

Português

Suid-Afrikaanse Dutch taal

کوردی-سۆرانی

Ελληνικά

español

Frysk

dansk

አማርኛ

Bamanankan

euskara

Italiano

Tiếng Việt

অসমীয়া

català

Suomalainen

Eʋegbe

Hrvatski

Cebuano

Gàidhlig na h-Alba

bosanski

galego